“Burn-off” is the reduction in length of a weld stud, which occurs during the arc stud welding process.

STUDs – Before and after weld:

The Process

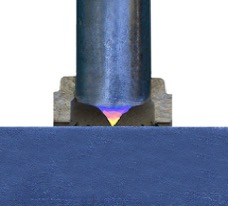

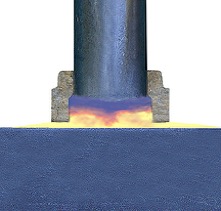

- Place stud & ferrule to work surface.

- When the trigger is pulled, the stud lifts, and draws a pilot arc.

- Pilot arc turns to sustained arc while stud remains lifted

- In a split second the stud plunges to base material, a fillet solidifies around base and the ferrule is removed.

Determining Proper Length Stud – Formula:

(After weld length + “burn off” = Stud Purchase length)

*EXAMPLE of a ¾” x 4.00” Shear Connector welded thru decking:

4.00” (after weld length) + 3/8” (burn off) = ¾ x 4-3/8” (stud purchase length)

Stud Reductions per Diameter:

| Stud Diameter | Approximate Reduction |

|---|---|

| 3/16”-1/2” | 1/8” |

| 5/8”-7/8” | 3/16” |

| 1” and over | 1/4” |

| 3/4″ thru-deck | 3/8” |

Examples of After Weld Lengths Bare Steel vs. Thru Deck:

Example 1

| Approx. after weld length when welding to bare steel. | Approx. after weld length when welding thru metal decking. | |

|---|---|---|

| 4-3/16″ | 4.00″ | 3.813″ |

| 4-3/8″ | 4.188″ | 4.0″ |

| 4-7/8″ | 4.688″ | 4.50″ |

Example 2

| Approx. after weld length when welding to bare steel. | Approx. after weld length when welding thru metal decking. | |

|---|---|---|

| 5-3/16″ | 5.00″ | 5-7/8″ |

| 5-3/8″ | 5.188″ | 5.688″ |

| 5-7/8″ | 5.0″ | 5.50″ |