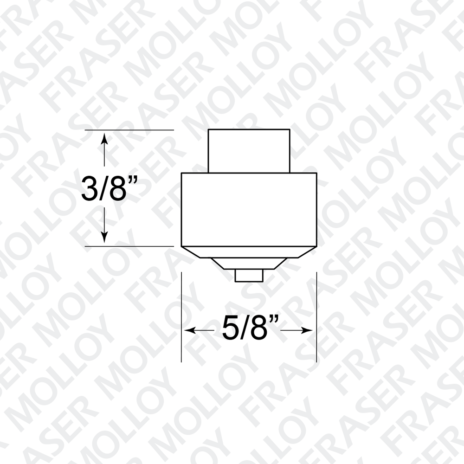

Series 68 (Base Diameter 3/4″)

| SERIES 68 SPECIFICATIONS 3/4″ Base Diameter |

||

|---|---|---|

| SERIES NUMBER | TSA-68 A Series Alloy |

TSI-68 I Series Alloy |

| WELDING SIZE | 3/4″dia. x 1/2″ high (AW) (19 mm dia. x 13 mm high) |

3/4″ dia. x 1/2″ high (AW) (19 mm dia. x 13 mm high) |

| MATERIAL | Chromium carbide in an alloyed iron matrix, molybdenum modified. | Chromium carbide in an alloyed iron matrix. |

| HARDNESS | Rockwell C 48-52 | Rockwell C 55-60 |

| DUCTILITY | 13% to 15% (in compression) | 1% to 3% (in compression) |

| FEATURES | Very good abrasion resistance combined with very good impact resistance. Designed for applications that allow use of higher profile. | Excellent abrasion resistance. Designed for applications that allow use of higher profile. |

| WELDING PARAMETERS | ||

| PREHEATING | None required. Minimal during cold weather operations to remove condensation. | |

| CAPABILITY | Horizontal, vertical | |

| POWER/TIMER | 1000 to 1100 amps/0.7 to 0.8 seconds | |

| APPLICATION RATE | Up to 250 Tuffstudds per hour; coverage up to 4ft2 per hour (0.4 m2/h) | |

| SPACING | For normal abrasive conditions, install in a close packed staggered pattern with about 100 Tuffstudds per square foot (1075/m2). For severe abrasive conditions, install in a close packed staggered pattern with about 108 Tuffstudds per square foot (1290/m2). More open spacing is not recommended for most applications. | |

| PACKAGING | ||

| CARTON SIZE | 250 Tuffstudds complete with ceramic ferrules | |